Discover a new era of precision with Eddyfi's high-quality NDT probes and transducers, offering a diverse range of frequencies, configurations, and connection styles. Lightweight yet solidly constructed, our equipment exceeds global inspection requirements. Delve into the efficiency and safety of ultrasonic testing using our phased array (PA) probes, incorporating advanced piezocomposite technology for flaw detection, thickness gauging, and material research. Our linear arrays, notably dual array probes for welding and PA probes for corrosion, provide rapid scan speeds, sharp imagery, and unmatched accuracy. Eddyfi not only delivers equipment but a complete solution, with design services and customizable probe options to meet unique application needs. Elevate your NDT standards with Eddyfi Technologies, where precision meets innovation.

Download PAUT Probe Catalog

Details

General-Purpose Linear Array Probes

Our versatile general-purpose linear arrays are engineered to excel across a spectrum of applications, including weld inspection, tube and pipe examination, turbine blade assessment, rail inspection, and pressure vessel scrutiny. With variability in frequency, element count, and pitch, these arrays offer tailored solutions for diverse industrial needs, ensuring electronic control for precision in phased array testing.

See pricing

Phased Array Weld Inspection Probes

Paired with phased array wedges, these arrays excel in thorough inspections of welds, plates, and forgings. Customizable options meet various inspection requirements, delivering precise and reliable results. Cutting-edge piezocomposite technology ensures efficiency and accuracy in weld inspections.

See pricingSmall Footprint PAUT Probes (ABFP)

ABFP transducers are compact probes designed for inspections in confined spaces, excelling in examining welds, tubes, pipes, aircraft components, tanks, and more. Customizable arrays and wedges cater to specific inspection needs, while the advanced piezocomposite linear-array ceramics enhance resolution and steering ability, making these probes efficient and precise for challenging environments.

See pricing

Low Profile Array Probes

Tailored for small-diameter pipes, low-profile arrays excel in flaw detection and weld inspections. The A15 and A25 cases, suitable for confined spaces, along with customizable wedges, enhance adaptability. Using advanced piezocomposite ceramics, the linear arrays provide electronic control for precise inspections in tight spaces.

See pricingTime-of-Flight Diffraction (TOFD) Probes

Eddyfi Technologies TOFD probes excel in determining crack dimensions in metallic welds. Featuring highly-damped broadband transducers and quick-swap screw-in wedge attachment, they showcase cutting-edge technology for seamless inspection processes.

Learn how to set the perfect scan plan for weld inspection using TOFD, PAUT, and TFM here.

See pricing

Corrosion PAUT Probes

Corrosion arrays are strategically optimized to enhance efficiency and maximize the probability of detection in scanning applications for corrosion and erosion. Tailored for large plates, bars, and other components with extensive surface areas, these arrays significantly reduce inspection time compared to single-element inspections, offering a streamlined and effective solution for comprehensive assessments.

See pricing

Flexible Array PAUT Probes

FlexArray transducers, designed for versatility, excel in inspecting curved metals and composites, adapting effortlessly to various radii. Eddyfi Technologies' probes are engineered for diverse inspections, ensuring heightened flaw detection and quicker inspection times on large surfaces. Their adaptability makes them the preferred choice for meticulous inspections on intricate surfaces, standing out with advanced piezocomposite ceramics for optimized resolution and steering ability in non-traditional scenarios.

WheelArray™ PAUT Probe

The WheelArray transducer is an advanced phased array solution designed for inspecting composite materials and flat metal plates, boosting inspection productivity for large surface areas. It features a user-friendly design, accommodating composites up to 50 mm (1.97 inches) thick, a 3-meter (118-inch) cable (customizable), and weighs only 1.7 kg (3.8 pounds) when filled.

With five test frequencies and a P68 magnetic rotary encoder, it is tailored for efficiency in composite inspections, showcasing Eddyfi Technologies' dedication to advancing inspection technologies.

Immersion Linear Phased Array Probes

Integrated into automatic and manual scanning systems, these arrays excel in non-contact inspections. Ideal for intricate geometries, they provide superior near-surface resolution with electronic control for precision in phased array testing.

See pricingLinear Contact Membrane Probes

Linear contact membrane transducers are specialized arrays designed for inspecting threaded bolts and rough surfaces. They feature a replaceable membrane for effective coupling and can be customized with either side-mounted or top-mounted cables. Ideal for industrial phased array testing, these transducers enable electronic control over crucial parameters, powered by advanced piezocomposite ceramics for precise inspection outcomes.

See pricing

Total Focusing Method (TFM) Array Probes

TFM array probes utilize an algorithm to interpret inspection data obtained through full matrix capture (FMC). This method enhances imaging capabilities by focusing at all points within the inspection area, providing a comprehensive and detailed representation of the inspected material or component. Discover how to inspect in-service electric resistance welded (ERW) pipelines with TFM without slowing down in this application note.

See pricingMatrix Array Probes

Matrix array transducers enhance phased array inspections with full matrix capture, improving probability of detection (POD), flaw sizing, characterization, imaging, and inspection scan speed. Eddyfi Technologies excels in design validation through 3D computer simulation, ensuring precision and adaptability for a range of inspection scenarios, from a simple 4x8 element array for weld inspection to a complex 800-element array for heavy-wall forgings.

See how matrix probes put nozzle weld inspection into perspective with a 3D environment here.

Dual Matrix Array Probes

Implementing transmit-receive configurations for enhanced sensitivity and signal-to-noise ratio (SNR), these probes excel in inspecting coarse-grained materials, corrosion-resistant alloys, and dissimilar metal welds. The beam-skewing capability improves flaw detection for diverse inspection needs.

This blog demonstrates the benefits offered by matrix array probes with steering capabilities in both active and passive planes.

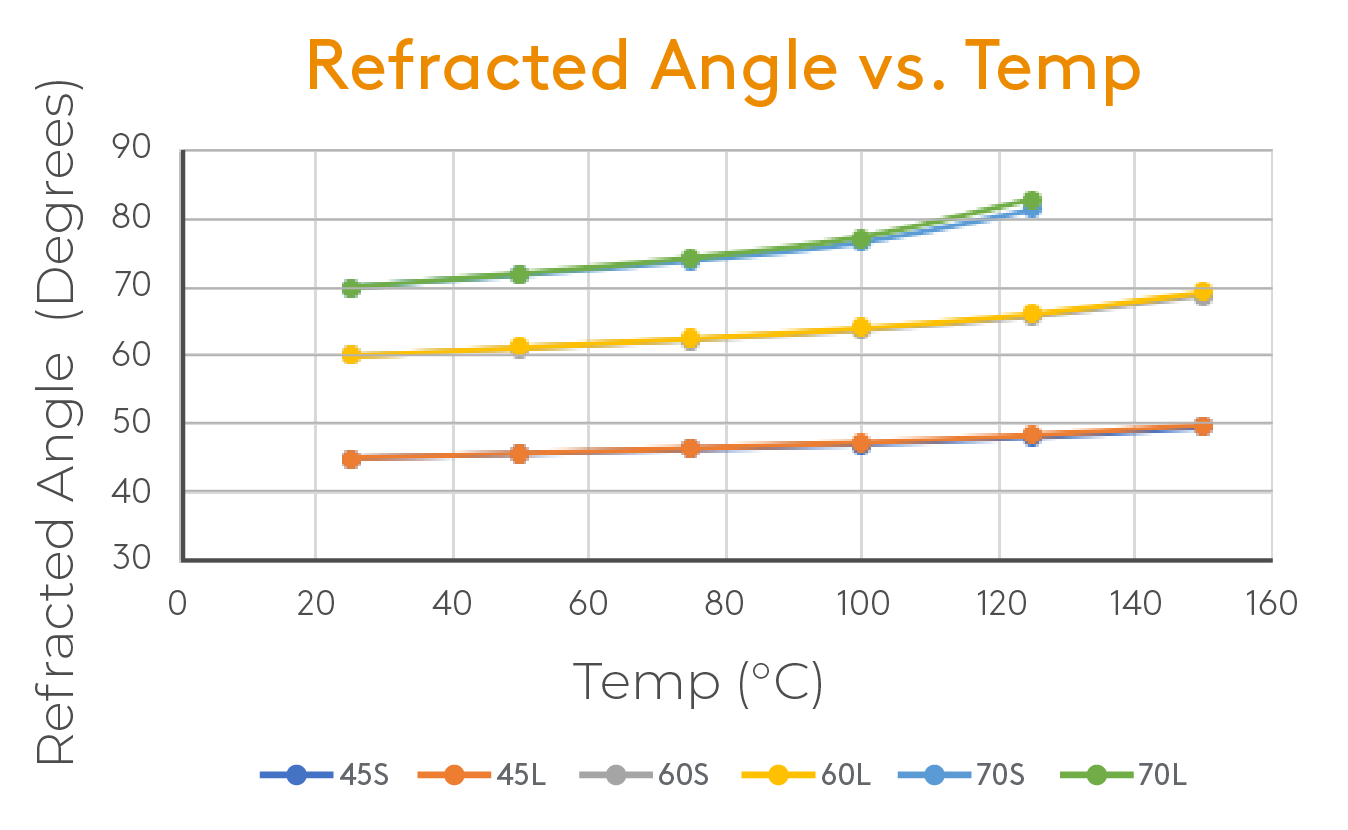

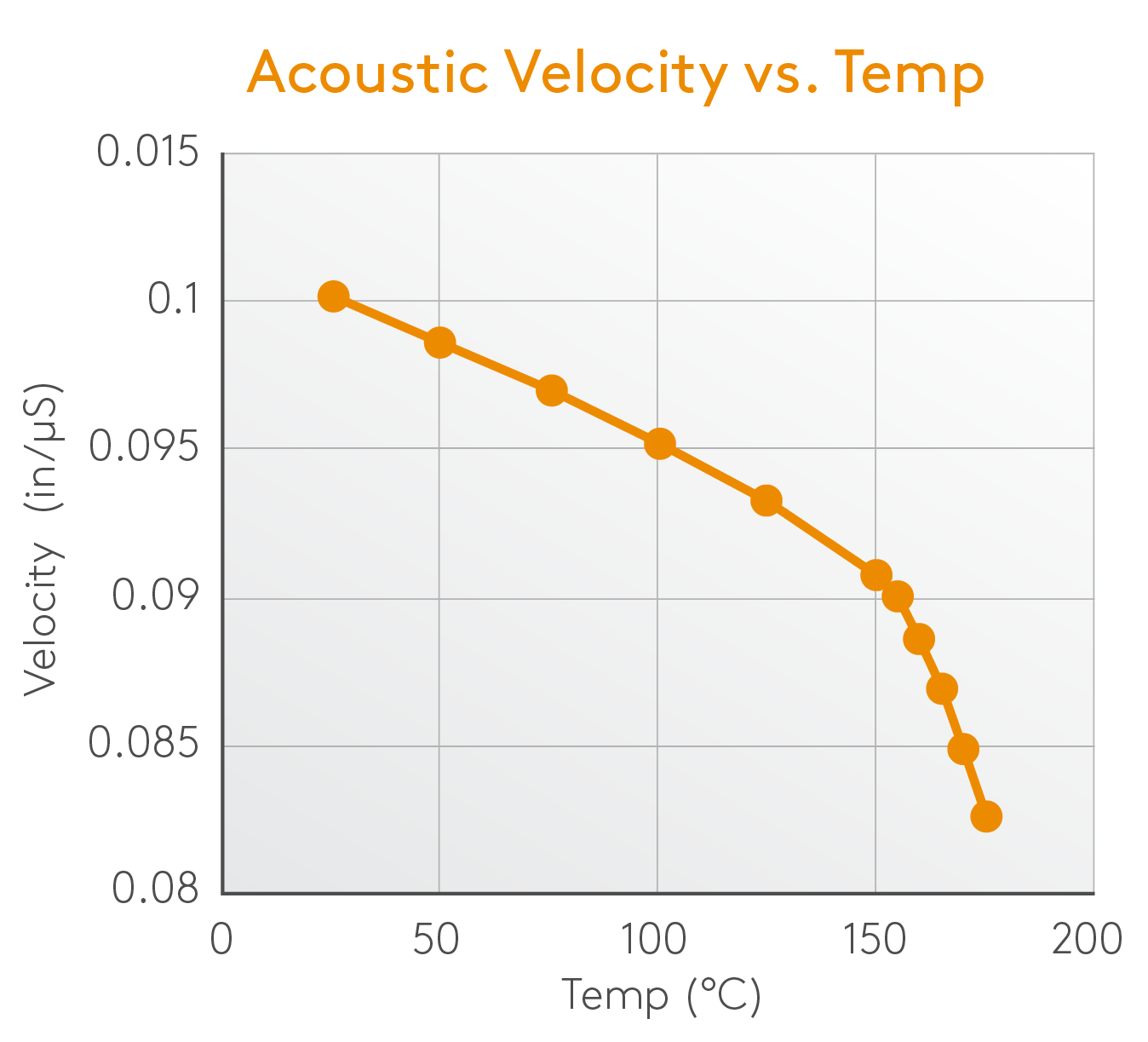

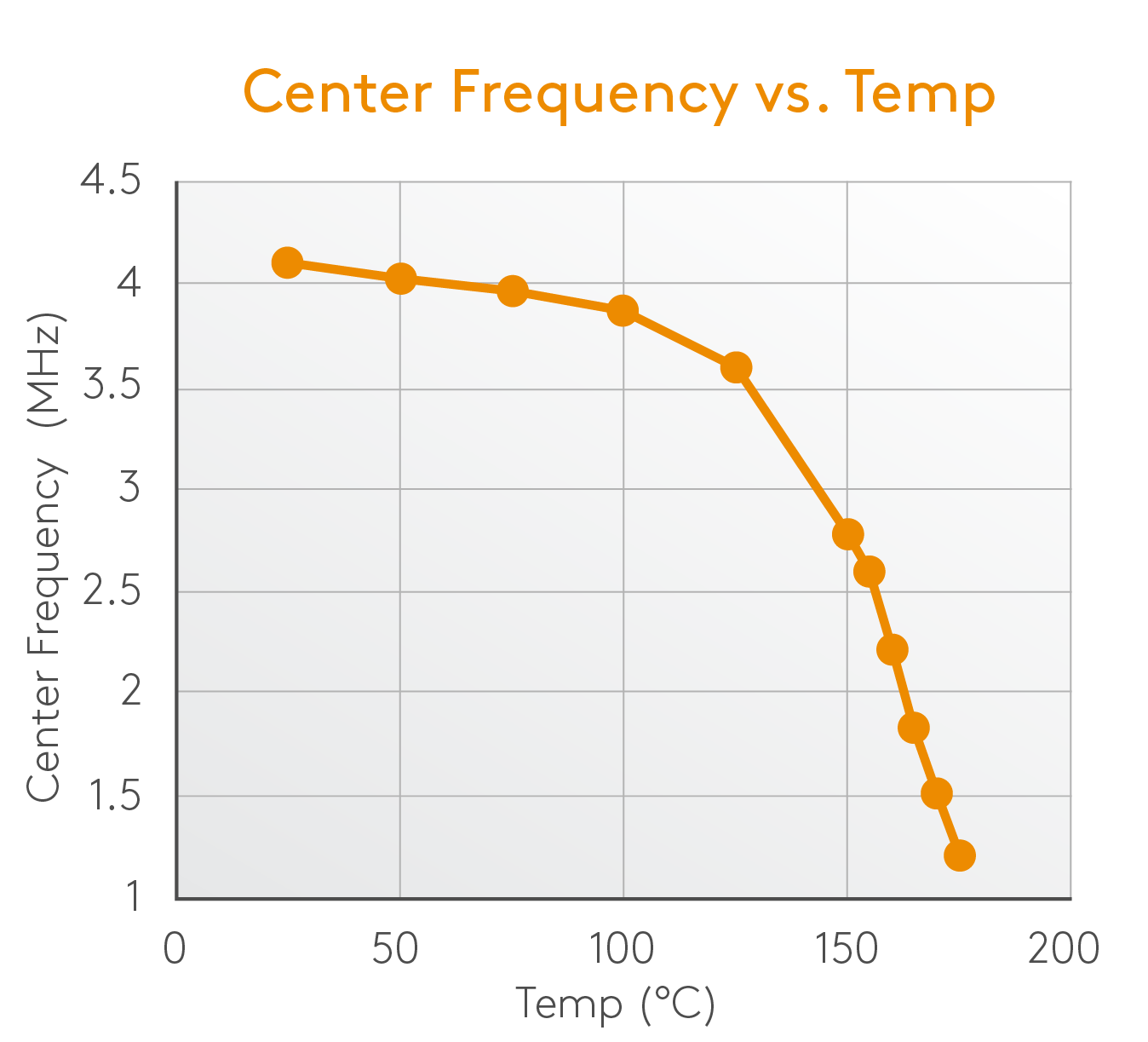

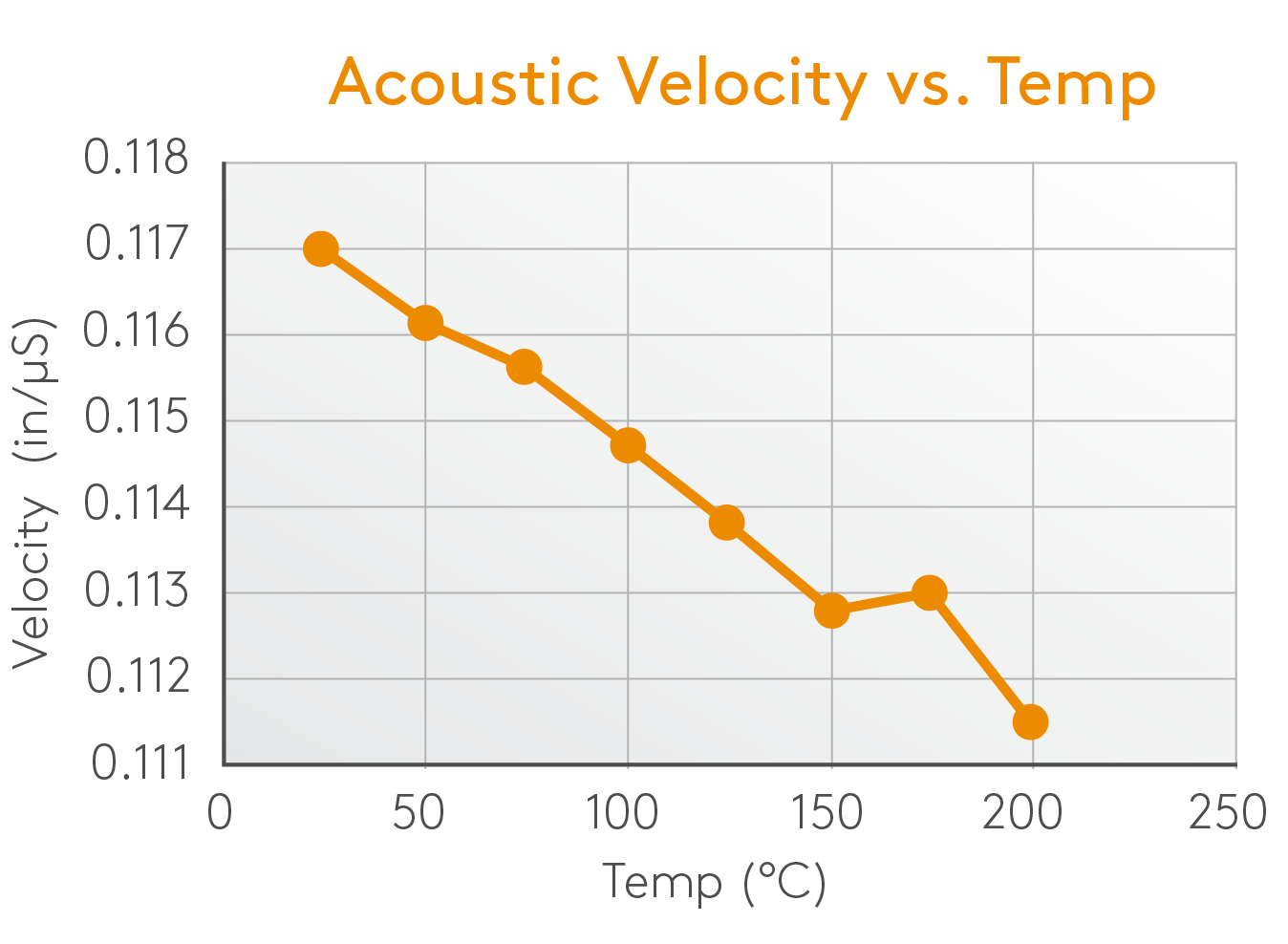

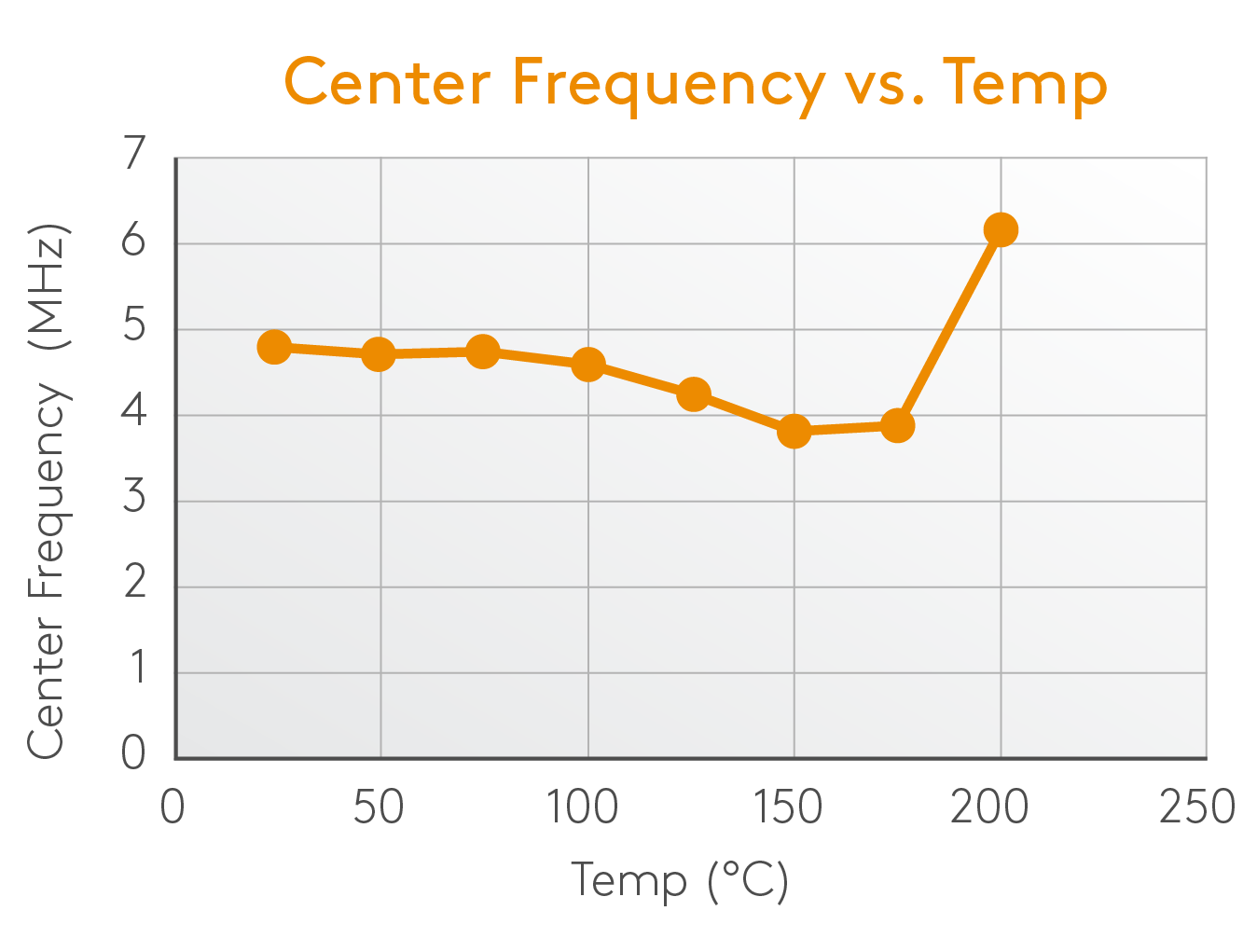

High-Temperature Linear Probes

High-temperature linear arrays are versatile solutions for diverse applications like weld and tube inspections. Equipped with 2.5-meter (8.2-foot) cables and IPEX connectors, they offer Mid Temp [100-150°C (212-302°F)] and High Temp [150-200°C (302-392°F)] wedge options. Available in 30-70° and 0° refracted angle models, these arrays provide flexibility for tailored inspections.

Mid-Temp Wedges - Peek (Natural), 100°-150°C (212°-302°F)

High-Temp Wedges - Celazole U-60, 150°-200°C (302°-392°F)

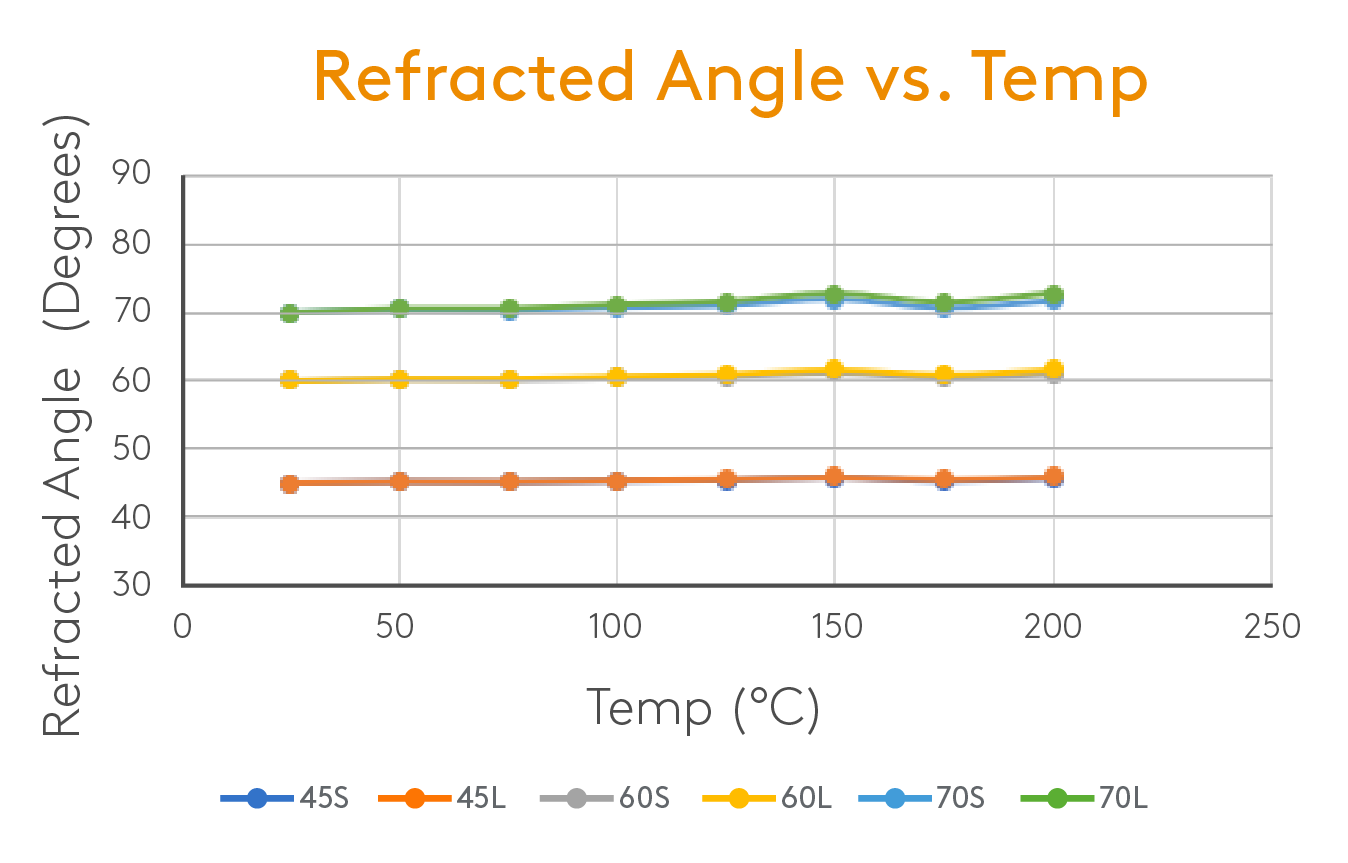

High-Temperature Dual Linear Probes

The high-temp dual-linear corrosion array, built for corrosion inspections up to 200°C (395°F), features specialized design for high-temperature environments. With 32 transmit and receive elements, it offers extensive beam coverage and enhanced inspection precision through a pseudo-focusing effect.

Special Applications

Eddyfi Technologies has made substantial investments in people, technology, and infrastructure, establishing a vertically integrated process for designing and manufacturing inspection systems. The in-house capabilities include CAD/CAM proficiency and a fully equipped machine shop with 5-axis CNC mills and lathes, facilitating swift prototyping of intricate geometries and materials. The presence of in-house ceramic fabrication facilities ensures a rapid and efficient turnaround for critical piezo-composite materials. Supported by a team of highly experienced applications engineers, our custom applications lab harnesses collective expertise to devise optimal solutions for the most challenging inspection scenarios, demonstrating our commitment to innovation and excellence. Bring us your unique challenge!

Ask an Expert

Custom 92-element array for tube and bar testing machines

Custom 256-element array for aerospace forging inspection

Curved immersion arrays for the inspection of carbon-fiber-reinforced polymers corners